CONCRETE

DISTRIBUTION SYSTEM

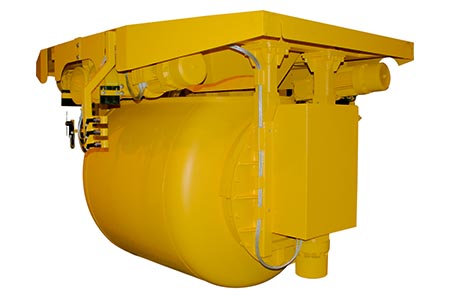

Concrete distribution in the Precast and Block industry is a critical factor, making the difference in having an efficient production plant. Rollover buckets are more suitable for Wet cast. Double Clamshell bucket is usually more effective in the dry cast applications due to the pyramidal shape of the walls. For double layer blocks and pavers, a twin bucket option is also available.

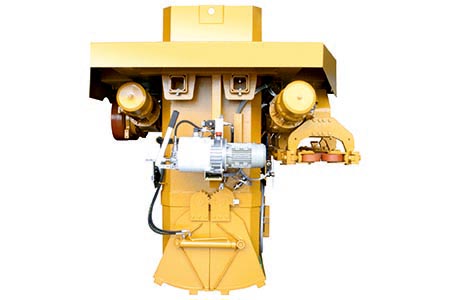

Twin horizontal rail or Twin vertical rail track. They can reach the speed of 240 m/min. Maximum inclination of the rail track is 25° (8° without chain system). Hybrid models are available whenever both types of concrete (wet and dry) have to be transported and distributed inside the plant.